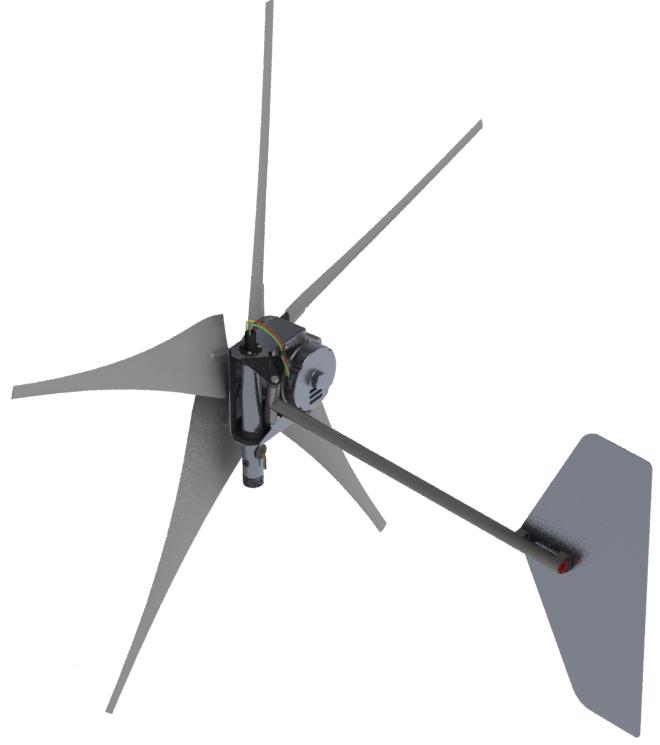

Emergency power is needed in homesteads across the country. Manufactured by Soliex, Inc., the 500 watt TT500 Turbine is a simple option for charging batteries in a 12v system. Paired with a 100 watt solar panel for all weather patterns make it perfect for keeping a 12v system fully charged in any application where off-grid battery power is desired.

- Corrosion resistant frame and components from 304 SS and 5052-H32 AL!

- All SS hardware!

- Black Acetal (POM) bearings/bushings are virtually maintenance free!

- Off-set rotor has a slicing effect (in relation to the mounting pole) that provides whisper quite operation!

- Hinged tail allows for automatic furling action!

- Designed to use GM alternators with the 10SI/12SI frame (preferably from an A/C equipped vehicles) or off the shelf purpose built!

- Built in over-speed protection is automatic!

Looking from the top, the images below depict the TT500 Turbine rotor positions at different wind speeds. From left to right the images would indicate no wind or low wind conditions, the center at higher speeds and the right image in a fully furled condition.

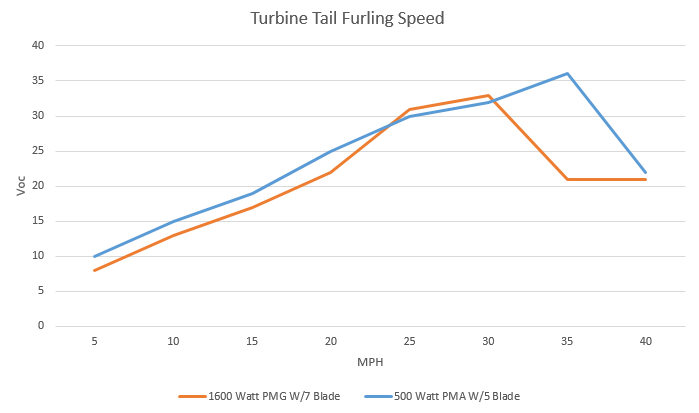

- 12v - 1.5Kw permanent magnet generator coupled to a 7 blade rotor of 60.5" (1.54m).

- 12v - .5Kw permanent magnet alternator (10SI altered with more copper windings from the supplier) coupled to a 5 blade rotor of 59" (1.5m).

The graph below shows the results of testing the prototype TT500 Turbine with the the rotor/gen combinations listed above. As can be seen, both turbines begin to produce voltage at a wind speed between 8 and 10 MPH then rise from there until the furling action results in a voltage drop around 35 MPH; this feature alone separates us from other turbine of this size operating in high winds.

If you have any questions or would like me to build you a TT500 Turbine of your own! Contact Soliex, Inc.

Wind Energy Battery Charger!

Wind Energy Battery Charger!